Innovative characteristics

2. Application

本设备是带卷首尾相接的专用设备,其用途主要是保证生产线连续运转,提高设备使用效率。广泛用于彩涂、脱脂、拉矫、重卷、酸洗等生产线的带卷头尾相接。

This device is a special equipment for end to end connection of coil, its main function is to ensure continuous operation of the production line, improve equipment efficiency. It’s widely used in the lines steel painting, degreasing, straightening, rewinding, pickling,etc. for the connection of coil head and tail。

3. Collected manufacturing

1) 设备规格Specification

SFH4.0x1650

2) 适用材料Material

(1)材质Material:热轧板hot rolled plate

(2)性能 Function

抗拉强度Tensile strength:σb≤650Mpa

屈服强度Yield strength:σs≤300 Mpa

(3)板厚Thickness:1.2-4.0mm

(4)板宽Width: 850-1650 mm

3) 设备性能Properties

(1)缝合厚度Stitching thickness:2.4-8.0mm(两张板厚之和Total thickness of 2 sheets)

(2)缝合宽度Stitching width:≤1650mm

(3)模具通过宽度Mold through width:≤1850mm

(4)模具开口度Mold gap::100 mm

(5)缝合时间Stitching time:≤20s/次

(6)缝合排数Stitching rows:每次一排或两排1 or 2 rows /time

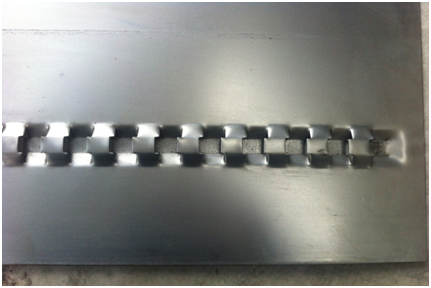

(7)缝口型式Stitching type:见附图See the following picture

(8)穿带形式Threading type:人工穿带manual thread

(9)设备工作中心高Height of working center:1433mm

(10)设备主机占地面积Floor area of equipment(长x宽x高)):约3280x1420x2412mm(不包括液压站The hydraulic station is not included.)

(11)进料方向Feeding direction:左进料Left

(12)系统压力System pressure:≥25 Mpa

(13)工作压力Working pressure:≤22Mpa

4) 设备组成Equipment components

1、机械部分Mechanical parts

本设备由主机架总成、缝合模具、同步机构、机械退料机构、压料装置、液压系统、缝合深度调整系统、安全锁止装置及电气系统组成。

The equipment consists of a main frame assembly, stitching mold, synchronous mechanism, mechanical stripper mechanism, hydraulic system, pressure forming device, suture depth adjustment system, security locking devices (safety pin) and the electrical system.

主机架总成由上下底座、侧机架、导向装置组成。上下底座、侧机架均由优质碳素结构钢焊接而成,经加工后通过8.8级高强度标准件组合到一起,精度高、强度大。

The main frame assembly consists of the top and bottom chassis, side frame, guide components. The top and bottom chassis, side frame are welded with quality carbon structural steel, after machining,they are combined together by connecting standard parts of CL8.8 with high precision and high strength.

模具是缝合机的主要设备之一,由上下模具板、退料板及冲剪刃组成,剪刃材质Cr12MoV,机械退料,设有模具保护装置。

通过连杆机构实现机械退料,避免了弹性柱或弹簧退料易出现卡死的弊端

模具带检测孔冲头,检测孔规格:Ø40mm。

同步机构由齿轮齿条组成,保证液压缸升降同步。运动部分添加安全保护罩、网及安全标识。

Mold is one of the main equipment of the stitching machine, consists of the upper and lower mold plates, strippers and punching blade, the material of cutting edge is Cr12MoV, mechanical stripper is designed with a mold protection device.

The mechanical stripping is realized through the connecting rod mechanism, which avoids the defects that it is easy to be stuck by elastic column or spring.

There is detection hole punch with mold, detecting holes Specification: Ø40mm.

The synchronous mechanism is composed by a rack and pinion, to ensure the synchronous lift of hydraulic cylinders. Moving parts are added with a security guard, network and security identity.

压料装置由压下液压缸和上下压板组成,其用途是将缝合缝压平。

缝合深度调整机构由位移传感器和信号反馈系统组成,实现缝合深度可设定、调整。

位移传感器选用深圳米朗产品,型号:KCT-200

安全锁死装置由转舌锁和接近开关组成。锁打开电源接通,可进入缝合程序,锁锁上全机断电。维修时,转舌锁锁上,从而确保设备保养、维修时人员的绝对安全。

本设备为液压缸下置式,设有上下可微调的托辊。托辊包聚氨酯。

The pressing device is composed of pressure hydraulic cylinder and upper and lower pressing plates, which is used to flatten the sew seams.

The stitching depth adjusting mechanism is composed of a displacement sensor and a signal feedback system, and the stitching depth can be set and adjusted.

The displacement sensor is product of Shenzhen Milang, model: KCT-200.

Safety lock device consists of the rotary tongue lock and proximity switch. After unlocking,the power is turned on and the procedure of stitching is started,when it is locked, the machine will be powered off, which can ensure the absolute safety of equipment maintenance and repair by locking the rotary tongue lock.

This equipment is mounted with cylinder at the bottom supported by upper and lower adjustable polyurethane rolls.

2、液压部分Hydraulic parts

Hydraulic/Mechanical system液压机械系统

1 All Hydraulic DC valves porting pattern to conform to following stds.所有液压直流阀接口要符合以下标准。

For WE DC Valves: For sub plate mounting (“P”)副板: Porting pattern to 接口形式 DIN 24340 form形式 A and和 ISO 4401

For WE DC Valves直流阀: For sub plate mounting副板安装, Porting pattern 接口形式to DIN 24 340 form A, ISO 4401 and CETOP-RP 121 H; NFPA T3.5.1 MR1 and ANSI B93.7 D05, D07, D08, or D10

For DB, DBW Relief Valve溢流阀: For sub plate mounting (“P”)副板安装: 接口形式Porting pattern to DIN 24340 form E and ISO 6264

For DR DP Pressure relief valve施压阀: Size 尺寸6 to DIN 24340 form 形式A and ISO 4401

Size 尺寸10 to DIN 24340 form 形式D and ISO 5781

2 Hydraulic Seal kit and filter dimensions required.要提供液压密封和过滤的尺寸

3 Hydraulic systems PID drawing required.要提供液压系统的PID图纸

4 Manufacturing drawing of mould and punch required.要提供模板和冲头的图纸

5 Hydraulic system should be Rexroth/Parker/Vickers/Yuken(Japan) make or compatible.液压系统要使用力士乐,派克,榆次(日本)或同等品牌

6 The hydraulic station stops after completion of each stitching, and it will be restarted when stitching, so the suture is interrupted and water cooling is not necessary for the hydraulic system.

液压系统由液压缸、液压站组成。其配置如下:

The hydraulic system is composed of hydraulic cylinder and hydraulic station with the following details:

液压缸选用韶关伟光产品,缝合缸型号:Y-HG1-G400/280X150FF4-HL10

压料缸型号:Y-HG1-G140/100X120LF1-HL10

Hydraulic cylinder is Shaoguan Weiguang brand,

Stitching cylinder: Y-HG1-G400/280X150FF4-HL10

Pressing cylinder: Y-HG1-G140/100X120LF1-HL10

液压泵为上海恒源产品,流量:100ml/转

Hydraulic pump is Shanghai Hengyuan brand, flow:100ml/round

电磁阀为北京华德产品。

The solenoid valve is produced by Beijing Huade

蓄能器为浙江奉化产品,规格:40L 2支

The energy accumulator is produced by Zhejiang Fenghua, specification:40L 2 pcs.

电机选用河北猛牛产品,电压:440V.频率:50HZ,功率:37KW

The motor is produced by Heibei Mengniu, Voltage:440V,

Frequency:50HZ, Power: 37 KW.

设吸油、回油过滤。

Oil absorption and oil return filter are designed.

其它元件选用国内优质产品。

Other components are domestic quality products.

3、电器部分Electrical parts

Electrical system电气系统

1 Details of depth adjusting and feedback system required.深度调节和反馈系统的细节信息要提供

2 The stroke of cylinder is short with thick plate, it is long with thin plate.板厚时液压缸行程短,板薄液压缸行程长.

3 Catalogue for detailed circuit diagram and consumable list required.流程图样本和耗材清单

4 Programming of PLC should be in English.PLC编程要为英文版本。

电气系统是设备的中枢系统,控制缝合、打开、缝合深度检测及设定。其

配置如下:

Electrical system is the central system of equipment, which controls stitching, stripping, stitching depth detection and setting.

The configuration is as follows:

PLC和触摸屏选用西门子产品。其它电器元件选用正泰产品。

本电气系统单独使用,不需要与主机联网通讯。

PLC and touch screen are SIEMENS products. Other electrical components are CHINT products.

This electrical system is used alone and does not require networking with the host.